FAQs & Tutorials

Client Care or call us at 1-831-763-2000

(Pacific Time, GMT-8).

or call us at 1-831-763-2000

(Pacific Time, GMT-8).

General FAQ

1. What is a Bed of Nails Tester?

1. What is a Bed of Nails Tester?

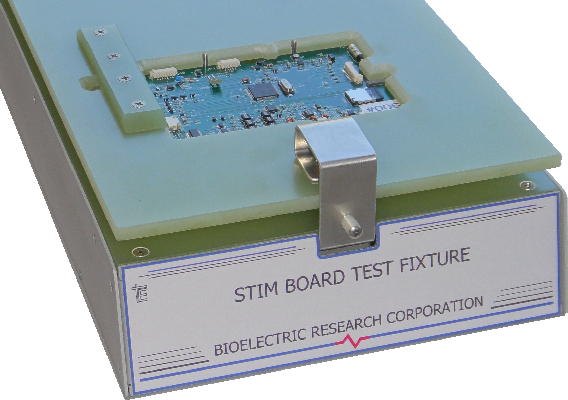

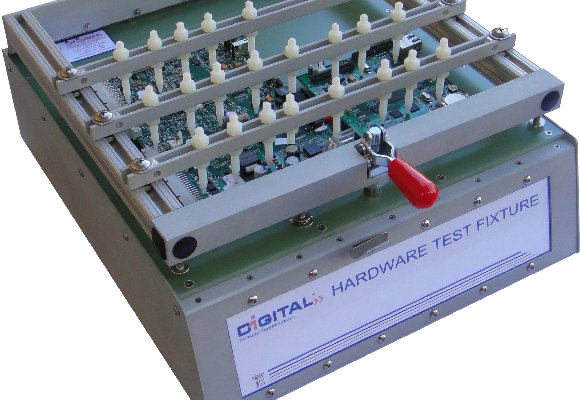

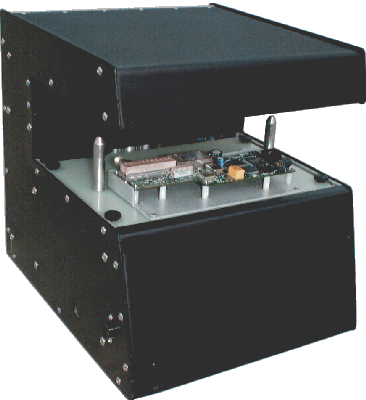

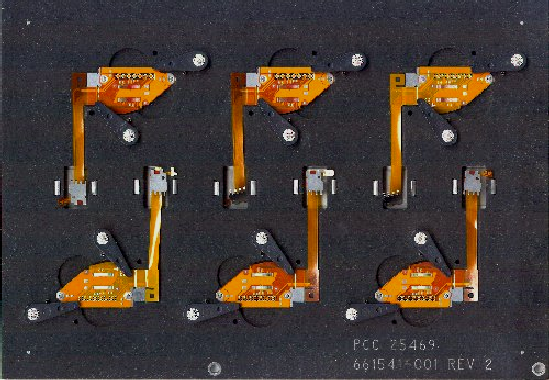

A bed of nails tester is a traditional electronic test fixture which has numerous pins inserted into holes in an Epoxy phenolic glass cloth laminated sheet (G-10) which are aligned using tooling pins to make contact with test points on a printed circuit board and are also connected to a measuring unit by wires. Named by analogy with a real-world bed of nails, these devices contain an array of small, spring-loaded pogo pins; each pogo pin makes contact with one node in the circuitry of the DUT (device under test). By pressing the DUT down against the bed of nails, reliable contact can be quickly and simultaneously made with hundreds or even thousands of individual test points within the circuitry of the DUT. The hold-down force may be provided manually or by means of a vacuum, thus pulling the DUT downwards onto the nails.

Devices that have been tested on a bed of nails tester may show evidence of this after the fact: small dimples (from the sharp tips of the Pogo pins) can often be seen on many of the soldered connections of the PCB.

Typically, four to six weeks are needed for the manufacture and programming of such a fixture. Fixtures can either be vacuum or press-down. Vacuum fixtures give better signal reading versus the press-down type. On the other hand, vacuum fixtures are expensive because of their high manufacturing complexity. The bed of nails or fixture as generally termed is used together with a in-circuit tester.

2. What is a Standard Test Sequence?

2. What is a Standard Test Sequence?

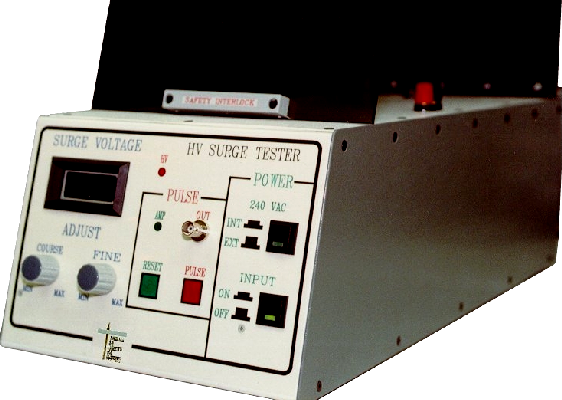

- Discharging capacitors and especially electrolytic capacitors (for safety and measurement stability, this test sequence must be done first before testing any other vertlists)

- Contact Test (To verify the test system is connected to the Unit Under Test(UUT)

- Shorts testing (Test for solder shorts and opens)

- Analog tests (Test all analog components for placement and correct value)

- Testjet (Agilent), FrameScan (Genrad/Teradyne) or ElectroScan (SPEA) (Test for defective open pins on devices)

- Power up UUT

- Powered analog (Test for correct operation of analog components such as regulators and opamps)

- Powered digital (Test the operation of digital components and Boundary scan devices)

- JTAG Boundary scan tests

- Flash,ISP and other device programming

- Agilent Medalist Beadprobe - Bead probe technology

- Agilent/Teradyne Powered Vectorless Test Solution - VTEP v2.0/Powered FrameScan

- Discharging capacitors as UUT is powered down

3. What is a Fixtureduino?

3. What is a Fixtureduino?

Fixtureduino's are Arduino based microcontrollers installed in our test fixtures.

These allow digital and analog testing. They are programmed via USB in C++.

Arduino Microcontrollers were chosen because:

Support FAQ

1. Do you have any distributors in my country?

1. Do you have any distributors in my country?

The Test Electronics network of distributors is constantly growing and now covers most areas of the world. See our "Contact Us" directory for the most up-to-date information.

2. How can I get assistance, if needed?

2. How can I get assistance, if needed?

Our technical support specialists are standing by to answer all of your questions about our Test Fixtures and Assembly line support products. Request assistance via our Tech Support Hub or call us at 1-831-763-2000 (Pacific Time, GMT-8).